A Brush with Innovation

April 4, 2022

5 minute ReadBY LINDSEY QUICK

Many components go into making an effective and functional car wash system. Arguably one of the most critical is the brush. Companies are regularly rethinking the technologies used in their brushes, including the materials, the direction their brushes move, and what brushes work best in which washes.

MATERIALS

One important material within the car wash brush industry is closed cell foam, which was introduced in the late 1990s. “Closed cell foam has revolutionized the car wash industry,” said Serko Kirikian, Owner of Kirikian Industries, a company involved in the car wash industry since 1967 that was founded with the creation of Neoglide technology. “Light closed cell foam was the perfect answer for a washing material to be used on the new automotive clear coats, which were more environmentally friendly but soft,” Kirikian said. “Since closed cell foam inhibits dirt from becoming embedded in the material, it doesn’t mark up the soft clear coats.” Another advantage of closed cell foam was the reduction in weight, which meant less wear and tear on the equipment and the need for less energy to operate.

“Car wash manufacturers took advantage of the benefits of the closed cell foam and developed equipment exclusively for the foam washing materials,” Kirikian said.

“Car wash manufacturers took advantage of the benefits of the closed cell foam and developed equipment exclusively for the foam washing materials,” Kirikian said.

Cloth didn’t go away, though, and is still in use quite a bit, as is a mix of both. Dennis O’Connell, President of Hoffman Services, a company that builds and remodels car washes in Illinois, said, “In our business, the majority of what we sell or replace in tunnel washes is cloth. However, we have customers who use foam at the door handle and above, and cloth below where it is a little harder to clean.”

Which brush material, of combination of materials you end up using, is generally a personal preference and a decision made based on the type of equipment you have and the length of your tunnel. Robert Pecora, President of Erie Brush, a supplier to the car wash industry since 1948, believes that because cloth is heavier and denser, it will remove more dirt and clean better in less space. On the other hand, in his experience, he said foam can be lighter on wash equipment than heavier cloth, extending the equipment’s usable life.

There are a variety of other materials in use out there, as well, and others in the works. Gallop Brush, a manufacturer of cloth and foam brushes founded in 2000, reevaluates the materials used to create their brushes almost constantly, said Director of Sales Ted Yamin, Jr. “There are quite a few new innovations happening in the brush space,” Yamin said. “Our teams are always thinking about and exploring what’s next for our customers, and we’ve incorporated many of these trends into our products already.”

For example, while customers have always been interested in a faster-drying material, some are now also looking for ones that are environmentally friendly as well, Yamin said. So Gallop created an option that is made with 100% recycled bottles for those customers. “We’re reducing our carbon footprint, which is important to our customers,” he said.

iWash Technology, a company with more than 40 years of experience in the car wash industry, is also looking to innovate brush materials. The company has designed an injection molded thermo-plastic that infuses round beads into cloth panels and foam panels for C-channel style brushes. “Currently, the sewn-and-stitched cloth onto a plastic spine used in today’s C-channel cores make it almost impossible to remove from the core when it’s time to replace,” said Co-owner of iWash Technology Sam Hadeed. “Our innovation allows for minimum surface contact inside the core slots, allowing the pearl beads to move and roll around inside the core slots to self-clean and flush out dirt.” The company has done extensive testing to ensure the pearl panel won’t get stuck inside the core, no matter how many cars are washed, extending the life of the core itself.

iWash is also exploring an embossed foam that is 100% closed cell and only 5 millimeters thick.

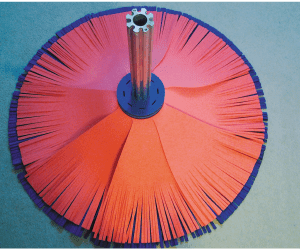

CONFIGURATION

The configuration of your brushes can also affect your brushes’ cleaning performance. “Today’s most common brushes use a brush core that has a fixed number of slots with cloth and foam panels sliding in vertically around a core,” Hadeed said. “The brush configuration is therefore fixed, limiting the ability to position cloth or foam panels to best contour and clean vehicles.”

iWash wanted to think outside the box and create brushes with unlimited stacking and configuration ability. They developed patent-pending brushes that allow stacking of cloth and foam panels horizontally and eliminated the use of a core. “We use foam spacers with varying thickness between each flat panel, which gives us the ability to manipulate the brush configuration and find the best fill and stack patterns for cleaning vehicles,” he said. The result is a brush that cleans effectively, is half the weight of traditional core brushes, and doesn’t make a slapping sound on the customers’ cars.

DIRECTION OF MOVEMENT

Another aspect that impacts brush capabilities — and is seeing innovative progress — is the direction the brushes move.

Leonardo Favagrossa, General Manager for Favagrossa Edoardo SRL, an Italian manufacturing company with 50 years of experience in making car wash brushes, said his company has introduced a new technique that combines the regular brush rotation with a new swinging motion, resulting in a friction that hits the surface from many different angles to increase the cleaning ability while assuring wash uniformity.

Leonardo Favagrossa, General Manager for Favagrossa Edoardo SRL, an Italian manufacturing company with 50 years of experience in making car wash brushes, said his company has introduced a new technique that combines the regular brush rotation with a new swinging motion, resulting in a friction that hits the surface from many different angles to increase the cleaning ability while assuring wash uniformity.

“The wavy movement helps to avoid unwashed gaps along a vehicle,” Favagrossa said.

“The bristles flap on the vehicle surface from a variety of angles to penetrate where other brushes can’t manage to go, like door handles, side mirrors and spoilers.” The positioning and movement of the brushes also creates a self-cleaning effect. “The continuous swinging motion helps prevent dirt from dragging across the car body and helps the brushes dry faster as well,” he said.

iWash is thinking about movement too. They developed a standalone reverse rotation rocker brush to clean surface areas on vehicle sides and wheels that standard rocker rotation sometimes miss, Hadeed said. This is especially helpful on areas like wheels, fenders, mirrors and door handles.

While car wash brushes are created using a variety of materials and for a number of applications, they all promise to clean the vehicles passing through your car wash. In order to create differentiation and meet customer expectations, car wash brush manufacturers are scrutinizing their own products to make them better — whether it’s in their ability to clean, their length of dry time, their carbon footprint and even the directions they’ll move in. While not every brush will work for every application, the choices for high quality products, no matter your set up, are widely available, and will only continue to grow as more manufacturers continue to innovate.